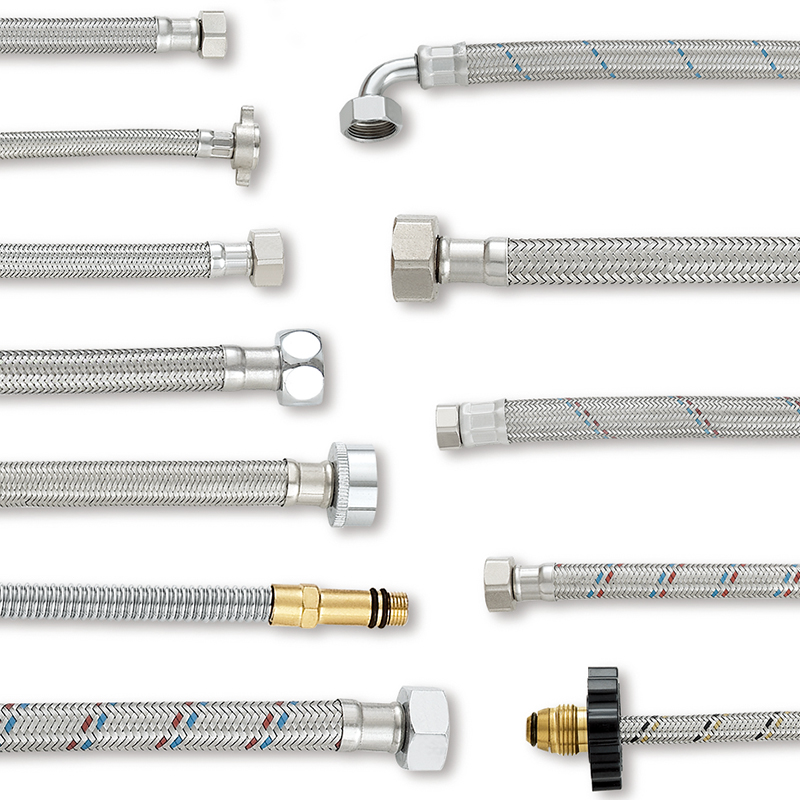

Come with me to understand the common braided hose handles in life. Everyone knows that braided hoses can be divided into low, medium and high grades according to the production process. Low-grade braided hoses use aluminum wires with smaller diameters than low-end wires, iron nuts, zinc alloy inner cores, and rubber inner tubes. Products with this configuration have a certain price advantage, but the grade is the lowest, and problems such as water leakage and oxidation are prone to occur. The mid-range braided tube is mainly made of 304 steel wire, EPDM material, and all copper fittings. The applicable period is generally more than 5 years. High-end braided hoses have specific uses, such as water purifier braided hoses. The general requirement is that the configuration of the mid-range comes first. Common configurations include 304 stainless steel wire, food-grade silicone inner tube, food-grade PEXB inner tube, 583 all-copper fittings, silicone gaskets, etc.

What is the purpose of the braided hose?

Braided hoses can be divided into single-headed hoses, braided hoses, and shower hoses (shower hoses) according to their uses. The single-headed tube is mainly used for kitchen and bathroom hardware such as faucets, sinks, etc. Her name comes from the fact that one end has external teeth, also known as a pole. The single-headed tube requires 304 stainless steel wire, EPDM inner tube, and all copper accessories. The braided tube is divided into stainless steel and alloy wire (aluminum wire), and it is also divided into upper and lower. Shower pipes generally have 201 and 304 stainless steel braids, EPDM inner pipes, and all-copper fittings. “Shenmo” brand shower pipes are generally made of 583 copper fittings, EPDM inner pipes, 201 and 304 stainless steel braids, of course, also include high-end full copper braids, and stainless steel gold-plated products, these are the comparison of braided hoses high-end products.

Post time: Sep-26-2022