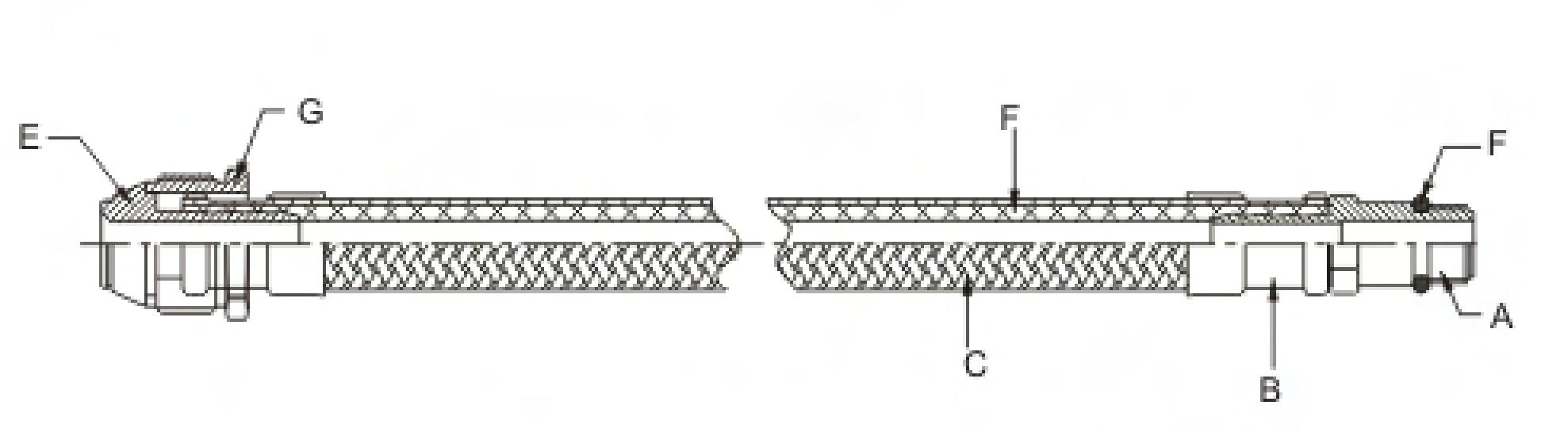

Stainless steel braided gas hose

Fitting

|

DN |

A |

B |

C |

D |

E |

F |

G |

|

φ 11 |

BRASS |

AISI-304 |

AISI-304 |

EPDM |

BRASS |

EPDM |

BRASS |

|

φ 12 |

BRASS |

AISI-304 |

AISI-304 |

EPDM |

BRASS |

EPDM |

BRASS |

|

φ 13 |

BRASS |

AISI-304 |

AISI-304 |

EPDM |

BRASS |

EPDM |

BRASS |

The difference between stainless steel braided tube and stainless steel bellows:

1. The braided layer of stainless steel braided tube is best made of high-grade material (304). The high-grade stainless steel has better stability and flexibility than low-grade stainless steel. How to quickly identify the quality of stainless steel, you can use stainless steel identification potion to identify, as long as a few drops of potion are dropped on the stainless steel material, it can be distinguished within two to three minutes. Stainless steel produces rust stains.

2. One strand of stainless steel braid is composed of 6 stainless steel wires, and there should be no crossover between them (stacked wires). Whether there are the above quality problems .

Stainless steel bellows material introduction

Stainless steel bellows or copper bellows (currently common in the market) are the main raw materials. The difference between stainless steel braided pipe and corrugated pipe:

Stainless steel bellows are harder than stainless steel braided hoses. The advantages of bellows are corrosion resistance and high temperature resistance, which are suitable for heating pipes. Larger diameter than braided hose = larger water flow. The installation precautions of the bellows are: it must be kept perpendicular to the joint. The disadvantage of bellows is that it is not easy to bend at the same part many times, otherwise the wall of the bellows will be broken.